The material that has been used for many years in the advertising and decoration sector, which is known with different names such as Plexi/Acrylic/ Plexiglass/ Mica, and is currently discovered in the construction sector; It is the general name of acrylic acids, polymers formed by processing with light, heat or metals. Depending on the type of acrylic, compound used and the conditions of the process, hard and transparent, soft and flexible solids or viscous, viscous liquid products can be obtained. The raw material of various compounds such as molded building materials, optical devices, jewelry, adhesives, coating materials and woven fiber are acrylic compounds. For example, orlon and acrylane are the trade names for acrylic yarns and plexiglass is the trade name for glass-like acrylic materials.The main members of the family of polymers known as polyacrylic are acrylic and methacrylic acids.The methyl esters of these acids polymerize easily in the presence of peroxide catalysts.

“Acrylic Sheets have 92% more light transmittance than normal glass and are 6 times more resistant to impacts.”

Acrylic Acid

It is an organic acid represented by the formula CH2 = CH COOH and is also called propenoic acid. In industry, it is obtained by reaction of acetylene and carbon monoxide with water in the presence of nickel catalyst or by hydrolysis of acrylonitrile compounds. It is the starting material in the production of polymers. Cast acrylic sheet is a polymethylmethacrylate based thermoplastic material.

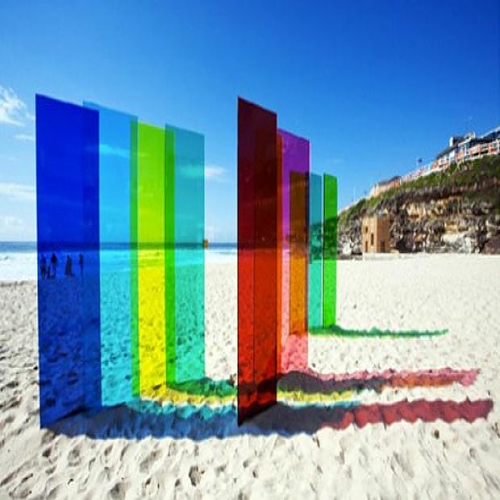

It is produced as colorless, transparent, colored and opaque in various sizes from 2 mm to 40 mm thickness with the casting technique. It has high light transmission (92% compared to glass). It is 6 times more resistant to impacts than normal glass. Its broken parts are not sharp edged, does not cause injuries. It conducts heat 20% less than glass of the same thickness. Plexi can be easily processed, can be formed into many shapes, bent and twisted when heated at about 150 °C. It can be formed with pressure and vacuum. It keeps its shape after cooling. Plexi’s maximum endurance temperature is 80 °C. Plexi is a flammable thermoplastic. Self-combustion temperature is 400 °C.

It can be ignited by flame at 250 ° C. Its surface is copper hard, it can be scratched with brush and sandpaper. Plexy has a bright appearance in all its transparent and colored forms. Its durability in atmospheric conditions is higher than all other plastics. For this reason, it can be used in a wide range of indoor and outdoor applications under very different climatic conditions.